Your shopping cart is empty!

Spectrometers: Key to Food Safety and Quality Control

Spectrometers are crucial in food testing due to their high sensitivity, rapid response, and portability. They detect contaminants, measure color for quality control, analyze components like sugar and acidity, and identify food adulteration using techniques such as near-infrared and Raman spectroscopy, ensuring food safety and quality through non-destructive, real-time analysis.

The application of spectrometers in food testing primarily lies in their high sensitivity, rapid response, non-destructive testing, and portability. These features make spectrometers an essential tool in the field of food safety testing, especially suited for on-site rapid detection and online monitoring.

Application Features

Spectrometers are widely used in food testing, covering areas ranging from contaminant detection to color measurement. As an essential tool in food testing, spectrometers offer several advantages:

High Sensitivity and Rapid Response: spectrometers can quickly detect various components in food, such as pesticide residues and microbial toxins. For example, pesticide residue rapid detection methods based on fiber optic spectroscopy can quickly determine the UV/VIS/NIR absorption spectra of pesticides, allowing observation of changes in absorption spectra with pesticide concentration for rapid residue detection. Additionally, fiber optic evanescent wave biosensors use the evanescent wave field to excite fluorescent dyes labeled on biomolecules at the fiber surface, achieving high sensitivity and rapid response by specific reactions attaching to the fiber core surface.

Non-Destructive Testing: The use of spectrometers does not damage the sample, making them ideal for testing where sample integrity must be preserved. For instance, in food quality evaluation, miniature spectrometers can measure the absorbance of micro-samples without destroying them.

Portability: The compact design of spectrometers makes them easy to carry and use on-site. For example, research into miniature spectrometers has brought spectral detection technology from the laboratory to the production site, where they are widely integrated into on-site or in-situ detection instruments. Furthermore, portable near-infrared spectrometry systems based on mobile networks overcome the time-consuming and destructive nature of traditional methods, enabling rapid on-site food screening.

Broad Application Range: spectrometers have a wide range of applications in food testing, including but not limited to pesticide residues, microbial toxins, food freshness, and food adulteration. For example, fiber optic biosensors can achieve rapid and precise detection of various contaminants in food. Moreover, spectrometers are also used for detecting volatile gases in food, allowing for quick quality assessments based on food volatiles.

Application Directions

Spectral technology enables real-time, non-contact, and contamination-free detection of material components, making it ideal for quickly identifying substances in food to determine the presence of harmful elements in food safety applications.

Contaminant Detection in Food:

spectrometers can be used to detect contaminants in food, such as pesticide residues and mold viruses. For example, near-infrared spectroscopy (NIR) can quickly and accurately detect harmful components in food, offering advantages like non-destructive testing, fast results, and simultaneous multi-component analysis. Additionally, fluorescence spectroscopy is used to detect aflatoxins and fumonisins, ensuring the safety of vegetables, tea, and dairy products. Raman spectroscopy is also applied in detecting the freshness of meat. Spectral technology, due to its non-contact and contamination-free characteristics, plays a crucial role in the routine detection of food quality, microorganisms, and drug residues.

Color Measurement:

Color is one of the key quality indicators in the food industry. Significant color differences in products that should appear identical can indicate potential quality issues, especially for perishable goods where visual appearance is closely linked to product quality. Since color is easier to measure compared to taste, smell, and texture, spectral methods are preferred for color measurement, ensuring quality control and food sorting.

In optical terms, opaque foods like bread, flour, tomato juice, cheese, and meat are analyzed using reflected light; semi-transparent products such as juices, wines, jams, custards, and processed foods can be examined with a combination of reflected and transmitted light; and fully transparent items like clear juices, wines, and jellies are typically measured using transmission spectroscopy.

Optosky’s ATP3034/ATP2000P spectrometers can measure the color of fruits, vegetables, and meat to assess product quality and processing methods. By shining a light source onto the food's surface, the reflected light is transmitted to the spectrometer, where detailed color information can be viewed directly on a computer screen through measurement software. Color measurement is critical for monitoring product quality during processing, evaluating the ingredients and processes of formulated foods, and ensuring consistent color in bread, pastries, and pet foods.

Component Analysis

Determination of Sugar, Acidity, and Vitamin C Content in Fruits

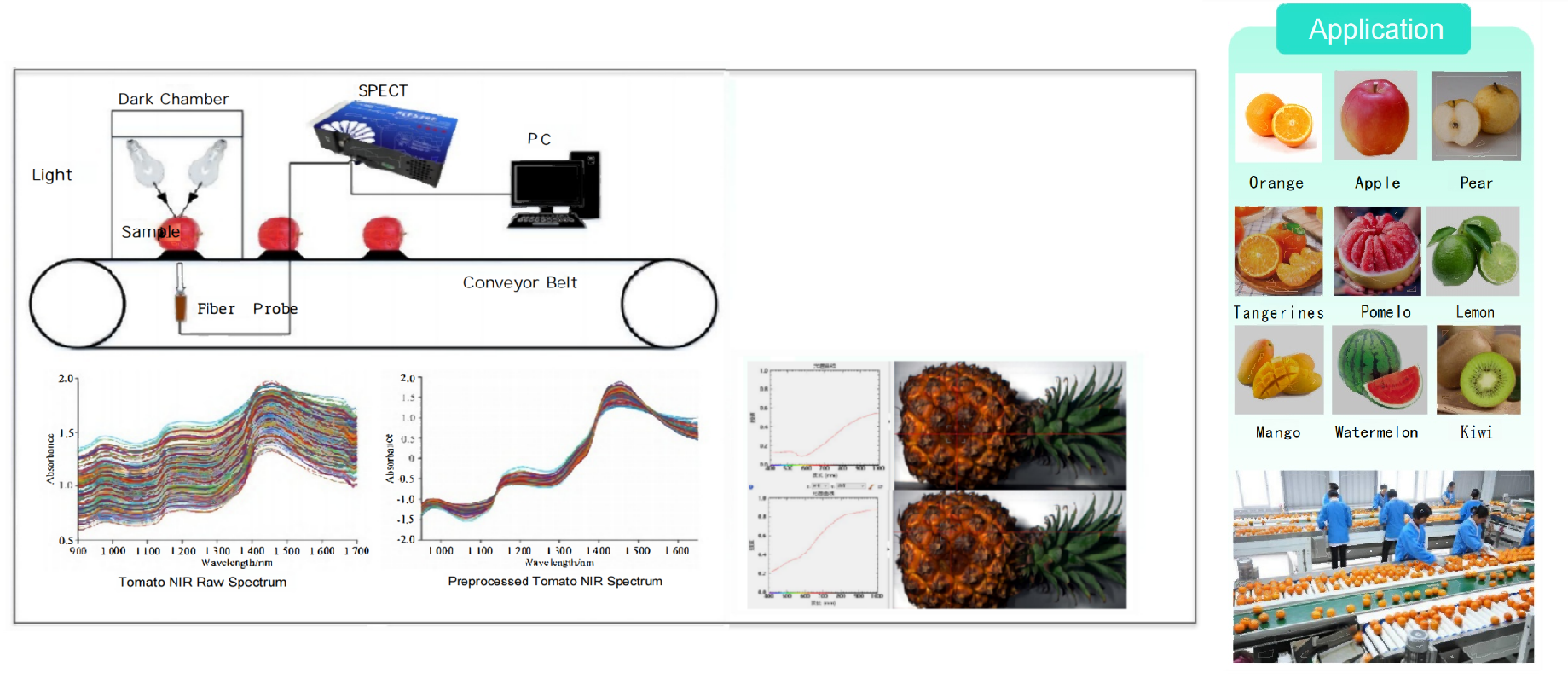

spectrometers can be used to analyze various components in food, such as protein, fat, and sugar. For example, near-infrared (NIR) spectroscopy is widely applied in the transmittance measurement of liquid samples, the analysis of crystalline substances, and the detection of high-transmittance foods.

In a basic testing setup, a light source illuminates the sample (such as fruits, beverages, tea, or flour), and the transmitted light is collected and analyzed by the spectrometer. By comparing the sample’s transmission spectrum with that of a standard reference, the absorption spectrum of the sample can be obtained. Due to the varying absorption of light by different internal components (such as moisture, total sugar, total acid, carotenoids, etc.), the specific types and quantities of these components in the food sample can be determined.

Considering the strong penetration capability of NIR light and the fact that most substances have absorption spectra concentrated in this range, NIR spectrometers are commonly used to collect spectral data for food composition analysis. Additionally, infrared spectroscopy is also used to detect pesticide residues, protein content, preservative levels, and alcohol composition in food.

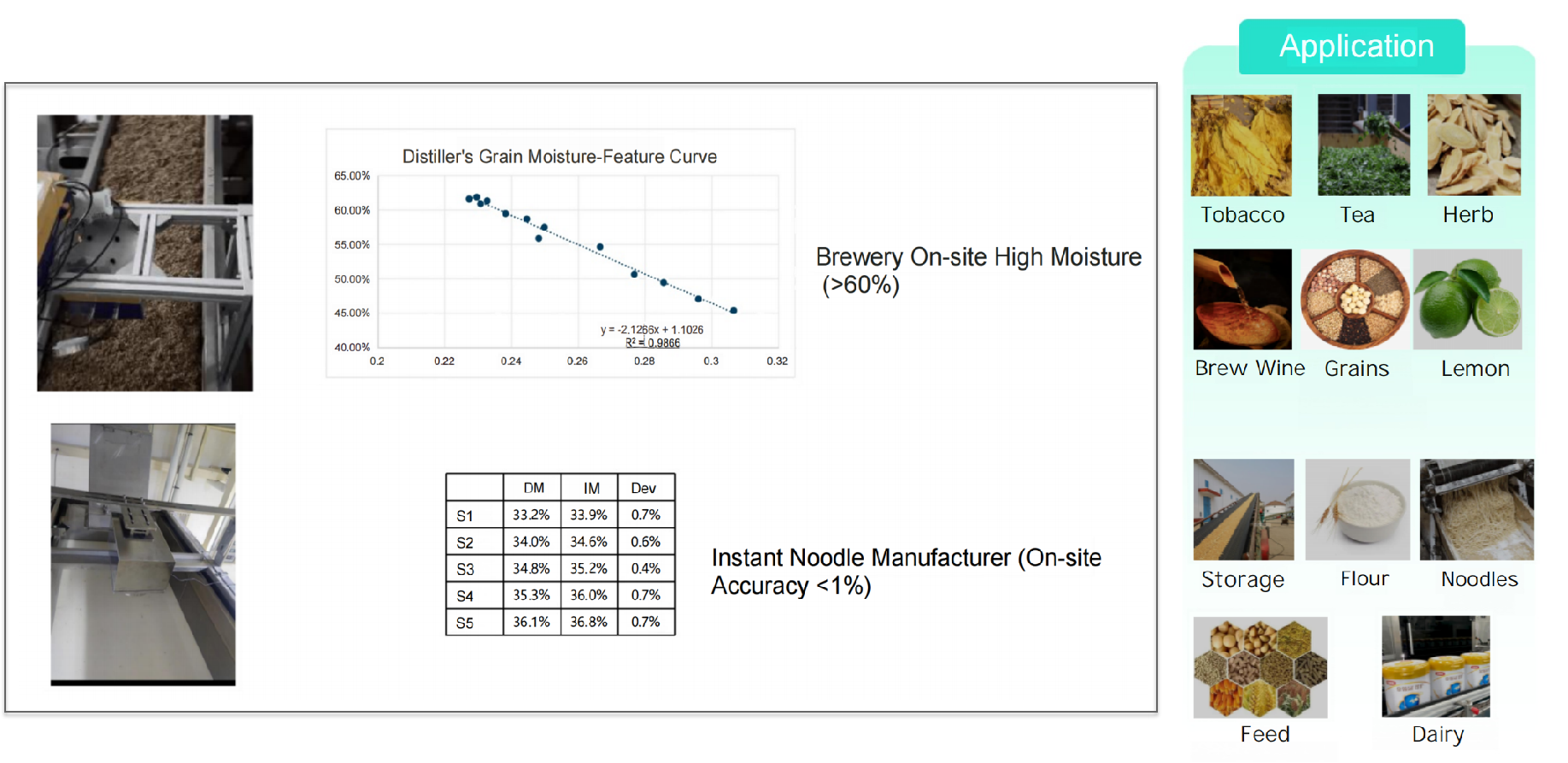

Online Infrared Moisture Measurement

Optosky's near-infrared spectrometers, known for their stability, high speed, high precision, high sensitivity, and portability, are widely applied in food composition testing, including grain analysis, non-destructive fruit testing, and alcohol detection. These features make Optosky's NIR spectrometers ideal for online infrared moisture measurement, providing real-time, accurate data for food quality control.

Food Adulteration Detection

Spectral technology also plays an important role in detecting food adulteration. For example, infrared spectroscopy can detect adulteration in foods, such as verifying the authenticity of olive oil, honey, and maple syrup. Additionally, fluorescence spectroscopy can be used to detect adulterants in foods like vanilla and spices.

Microbial Detection

Raman spectroscopy is an efficient method for microbial detection. By illuminating a sample paper with fiber optics and analyzing the scattered light to compare the scattered spectra of food samples, it allows for a scientific examination of microbial distribution in food. This method is characterized by high accuracy and can clearly identify the distribution of various microorganisms in food, making it particularly suitable for detecting products like flour and honey.

Due to its rapid, non-destructive, and non-contact characteristics, spectral technology holds significant application value in food safety testing. As mentioned above, spectrometers are widely and diversely used in food testing, covering various aspects such as contaminant detection, color measurement, microbial detection, component analysis, and adulteration detection. These technologies not only improve detection efficiency and accuracy but also ensure the quality and safety of food.

Search

Categories

Popular Posts

Latest Posts

Comments: 0

No comments